Preparation of titanium nitride (TIN) thin films by ALD process

Preparation of titanium nitride (TiN) thin films by ALD process via atomic layer deposition

Silicon nitride thin film windows are a common consumable for transmission electron microscopy, which allows researchers to observe the microstructure and properties of samples at high resolution. This paper will introduce the basic concept, characteristic advantages and application areas of silicon nitride thin film windows.

Silicon nitride (Si3N4) is an inorganic non-metallic material with high strength, high hardness, high heat resistance, high corrosion resistance and low coefficient of thermal expansion. Silicon nitride can form a uniform and dense film on the substrate by methods such as chemical vapor deposition (CVD) or physical vapor deposition (PVD). Such thin films can be used as a sample support platform for transmission electron microscopy (TEM), the so-called silicon nitride thin film window.

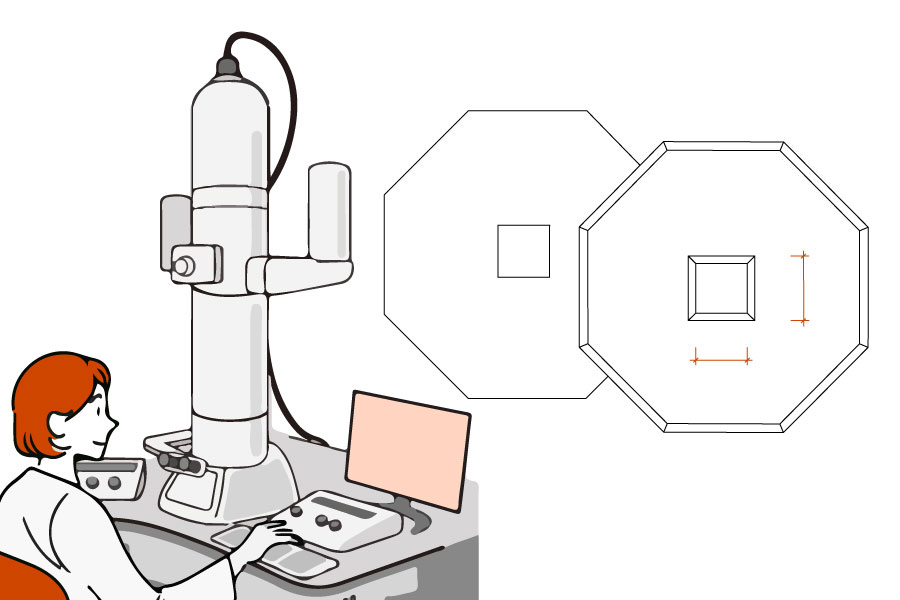

Silicon nitride thin film windows typically consist of a substrate frame with a standard diameter of 3 mm and a silicon nitride layer with an opening in the middle. The size and shape of the aperture can be tailored to the experimental requirements, typically square or circular, and the size ranges from a few hundred nanometers to a few millimeters. The thickness of the silicon nitride layer can also be adjusted according to the experimental needs, typically from 10 nm to 500 nm. This allows the researcher to place the sample in the opening and use the electron beam to penetrate the opening and interact with the sample to obtain images and information about the sample.

Silicon nitride thin film windows are prepared by thin film deposition technology and have the following seven main properties

High transparency:The refractive index of silicon nitride films is very low, about 1/3 that of air, so it can reduce reflection loss and increase transmittance, thus improving the efficiency of optical systems.

Good mechanical strength:Silicon nitride film materials have good mechanical strength and can withstand extreme environments such as high pressure, high temperature and strong acids.

Corrosion resistance.Silicon nitride thin film materials are able to maintain stable physical and chemical properties under extreme environments such as strong acids, alkalis and high temperatures, and are less susceptible to corrosion and oxidation, thus ensuring the stability and longevity of optical systems

High temperature resistance:Silicon nitride thin film windows are capable of maintaining stable physical and chemical properties in high temperature (1000°C) environments, making them suitable for optical systems and applications in high temperature environments.

High leveling:The high surface flatness provides a better sample support platform for more stable and uniform sample distribution on the window.

Washability:Various cleaning methods such as solvent cleaning and plasma cleaning can be performed to remove sample residues and contaminants.

Diversity:A wide selection of different sizes, thicknesses, surface finishes and aperture sizes are provided to meet various experimental needs and application scenarios.

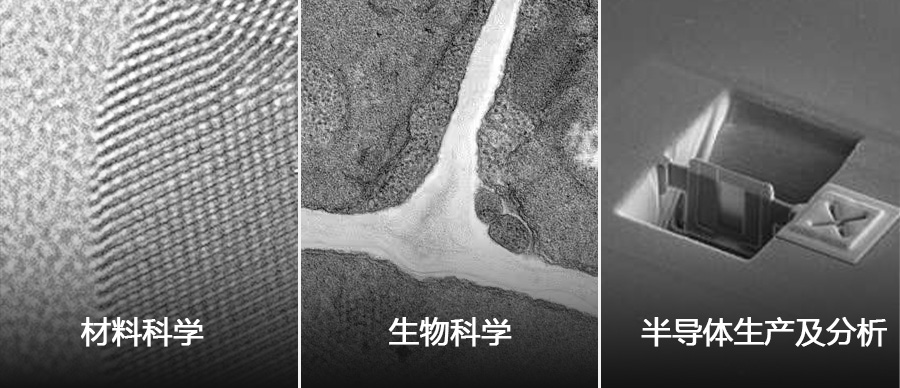

In conclusion, the silicon nitride thin-film window is an excellent observational tool in Materials Science (in-depth knowledge) , , Biological Sciences (in-depth knowledge) , , Semiconductor production and analysis (in-depth knowledge), ,Optical and other fields have a wide range of applications. Due to its high stability and low defectivity, silicon nitride thin-film windows will play an even more important role in future research and practice!

We offer Silicon Nitride Thin Film Windows / MEMS Customization ServicesPlease feel free to leave a message.

Preparation of titanium nitride (TiN) thin films by ALD process via atomic layer deposition

With this guide, you can make informed decisions to optimize your TEM imaging, SEM analysis, bioscience research, or semiconductor production.

Principles and Applications of Optical Coating Technology The process principles of optical coating mainly involve

.jpg)