Coating process

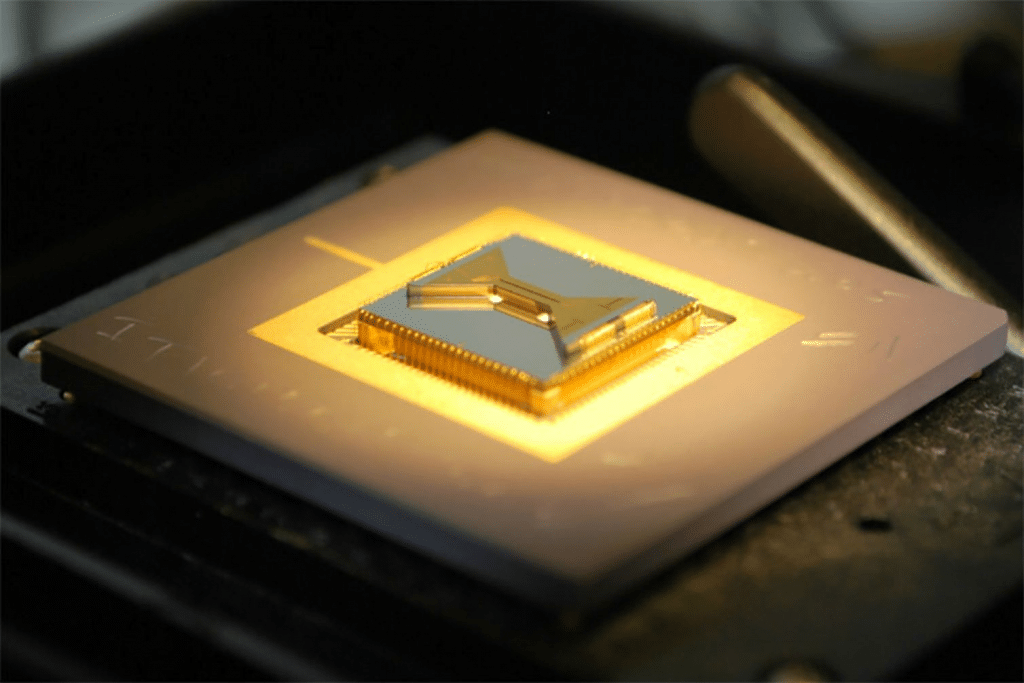

Physical vapor deposition (PVD)

What is PVD?

The origin of PVD (Physical Vapor Deposition) technology can be traced back to a series of experiments and studies in the late 19th and early 20th centuries. Its development has been closely related to the development of solid surface science, vacuum technology and materials engineering.

With the further development of solid surface science and vacuum technology, PVD technology has gradually become an important thin film deposition method. People began to use sputtering, evaporation and laser technology to achieve precise control of film composition, thickness and structure PVD technology has been widely used in the fields of microelectronics, optics, surface coating, etc., and has been continuously improved and optimized to meet the ever-developing industrial needs.

Our Technology

thermal evaporation

Sample size: 6″ and below

Uniformity: ≤±5%

Growable process:

Ag, Al, Sn, In, Bi, etc.

Electron beam evaporation

Sample size: 8″ and below

Unevenness: ≤±5%

Growable process:

Ti, Cr, Ni, Ag, Al, Ge,

Sn, Pt, Au, AuBe,

AuGeNi, AuSn, TiAl, TiNi, etc.

metal magnetron

Sample size: 12" and below

Unevenness: ≤±5%

Growable process:

Ti, Al, Cr, Pt, TiW,

Mo, W, Ta, Ni, Au,

Ag, Cu, ITO, TiN, ScAlN

et al. (and other authors)

dielectric magnetron

Sample size: 8“and below

Unevenness: ≤±5%

Growable process:

Nb2O5, TiO2, SiO2,

SiNx, TiN, PZT, etc.

Our Advantages

leading edge technology

Our state-of-the-art PVD technology enables a precisely controlled physical vapor deposition process that ensures excellent coating properties and quality.

Multi-disciplinary applications

Our PVD solutions are used in multiple industries, including automotive, aerospace, and medical devices, to provide protection and functional enhancement for a wide range of products.

Customized design

Our team can custom design a coating solution to meet your specific needs, ensuring that your technical and business objectives are met.

quality assurance (QA)

We strictly follow international standards and quality management systems to ensure that each batch of products meets high quality standards.

1. Communication needs

Select your needs for substrate size, deposition material, coating thickness, process options or more.

2. Program offer

We will give you the most reasonable quotation based on the best processing solution we can offer you.

3.Production and quality control

4. Delivery on time

Deliver the product to you within one week on schedule

Contact Us

Tell us what you need and we'll solve it

We will contact you as soon as possible

.jpg)