Influence of the annealing process on the platinum resistance

In the field of high-precision temperature measurement, thin-film platinum resistors are gradually replacing the traditional wire-wound platinum resistors due to their high stability and high accuracy. The annealing process is a key step in optimizing the performance of thin-film platinum resistors, and the thermal resistance characteristics of platinum thin films can be significantly improved through a reasonable annealing process.

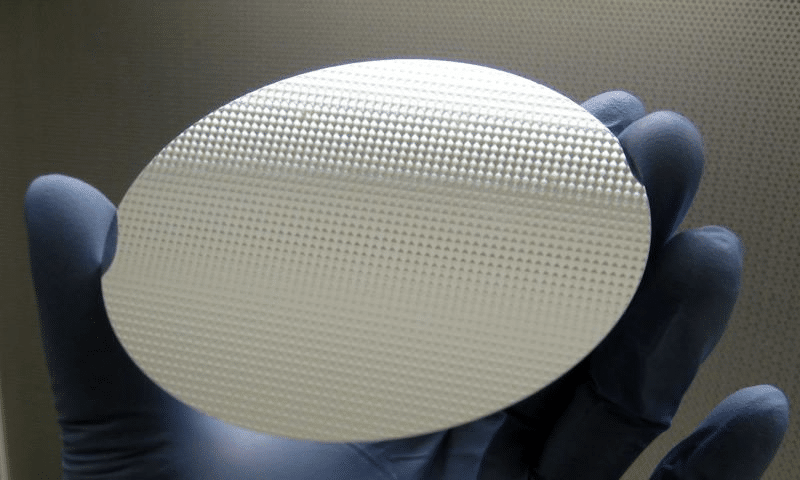

Preparation of platinum resistors

The process of preparing a platinum resistor usually consists of the following steps:

- Substrate preparation

- Photolithography

- magnetron sputtering deposition

- reprocess

- heat up(annealing (metallurgy))deal with

Influence of annealing process

thermal stability

- The annealing treatment improves the thermal stability of the film, making it behave more consistently in high-temperature environments.

- High-temperature annealing removes stress from the film and prevents structural deformation during temperature changes.

- Improves sensor reliability and life in high temperature environments.

heat conductivity

- During the annealing process, grain growth and improvement in crystalline quality enhance the thermal conductivity of the film.

- Films with large grains and high crystallinity have better thermal conductivity and reduced thermal resistance.

- Improve the response speed and accuracy of the sensor so that it can reflect temperature changes more quickly.

Temperature Coefficient of Resistance (TCR)

- The annealing treatment increases the temperature coefficient of resistance (TCR) of the platinum film, making the resistance value more sensitive to changes in temperature.

- A high TCR value helps to increase the sensitivity of the sensor to temperature changes.

- Improving the sensitivity and accuracy of the sensor allows it to measure temperature changes more accurately.

Resistance Stability

- Annealing reduces defects and inhomogeneities in the film and reduces resistance drift.

- The annealed film structure is more stable and the resistance value is more stable.

- Improves sensor stability and reliability over long periods of time, reducing the need for maintenance.

How to improve the annealing process

The annealing process significantly improves the microstructure and thermal resistance characteristics of Pt films by heating and holding treatments.

- Effect of annealing temperature on properties: Between 500 and 600°C, the higher the annealing temperature, the greater the sensitivity and the better the linearity, which can be adjusted according to the actual application environment.

- Effect of holding time: At 500°C, a 60-minute hold time can significantly improve sensitivity and linearity. However, extended holding times above 500°C will result in a decrease in performance.

- Influence of substrate roughness: Higher substrate roughness (e.g. 230 nm) can significantly improve sensitivity, but needs to be kept within reasonable limits to avoid affecting film continuity.

If you have any questions or need further information about the annealing process during platinizing, please feel free to contact us. We are committed to providing our customers with high quality, high performance solutions.

We offer Magnetron sputtering foundry customization services, Feel free to leave a message to inquire.

The Critical Role of Silicon Nitride Thin Film Windows in Semiconductor Production and Analysis

Silicon nitride thin-film windows have become an important part of the semiconductor industry due to their unique properties. Silicon nitride thin film windows have a wide range of applications, from production to analysis, and play a key role in the development of new semiconductor devices and materials.

Silicon nitride thin film window applications Materials Science丨Semiconductor丨Bioscience

Silicon nitride thin film window products are used in a wide range of applications in materials science, semiconductor production and analysis, and bioscience. Our high quality products provide high resolution imaging capabilities for a wide range of sample types and sizes.

Preparation of titanium nitride (TIN) thin films by ALD process

Preparation of titanium nitride (TiN) thin films by ALD process via atomic layer deposition

.jpg)