Magnetron sputtering丨process for making platinum temperature sensors

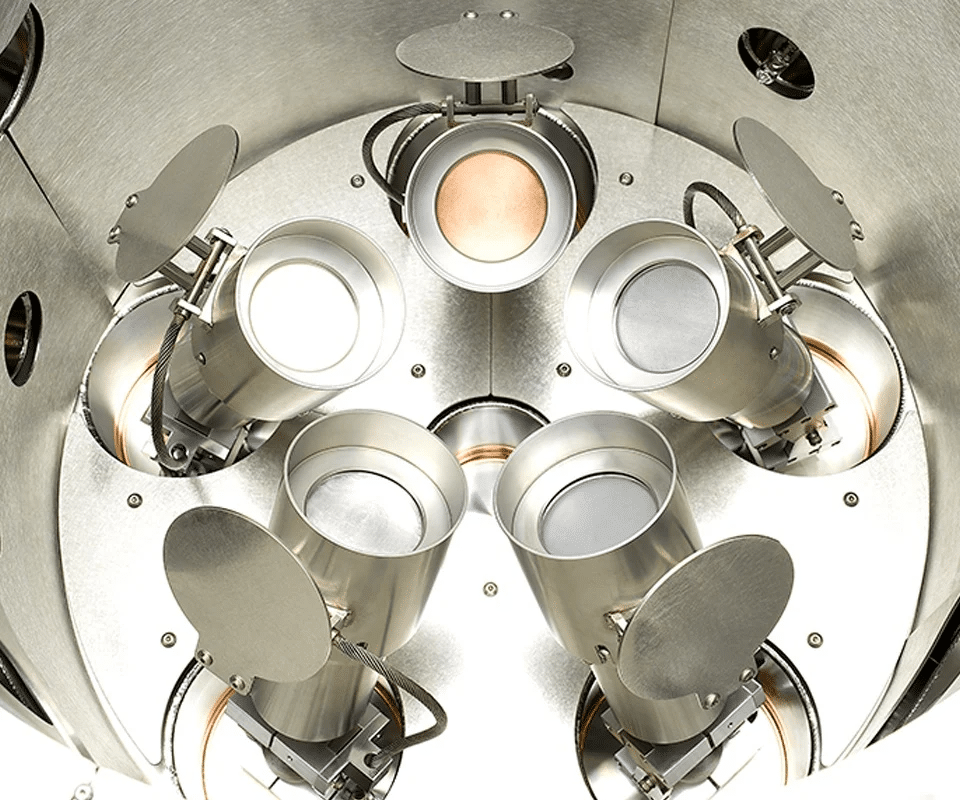

In the field of modern science and technology, temperature sensors play an important role as key measuring devices in various industries. And platinum temperature sensors are widely used in industrial control, automotive, medical, scientific research and other fields because of their high precision, stability and reliability. Among them, the use ofMagnetron sputtering processPlatinum plating for the preparation of platinum temperature sensors has many special effects.

Platinum temperature sensors

The Platinum Temperature Sensor, often referred to as a Platinum Resistance Temperature Detector (RTD), is a highly accurate and stable temperature measurement device. It utilizes the property of platinum metal's resistance to change with temperature to accurately measure temperature. The structure is as follows.

principle

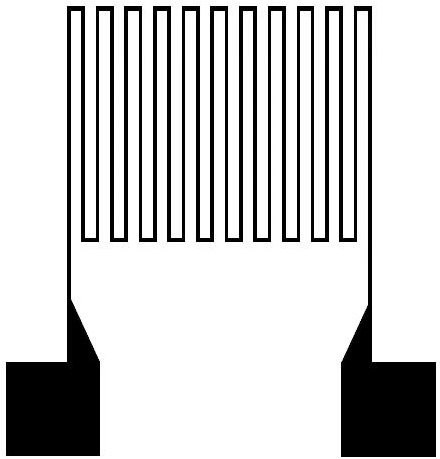

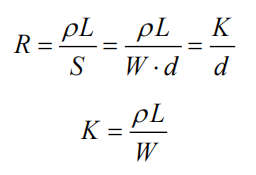

For platinum thin films different structural dimensions, such as line width and film thickness, can have a significant effect on the resistance of the platinum sensitive unit. Thin-film platinum resistance is directly proportional to the length L and inversely proportional to the cross-sectional area S, theρdenotes the resistivity of the film resistor; L denotes the total length of the resistor; W denotes the width of the resistor; d denotes the thickness of the resistor; and S denotes the cross-sectional area of the resistor.

Benefits

- highly accurate: Platinum temperature sensors have an extremely high measuring accuracy, typically between ±0.1°C and ±0.5°C, and are suitable for applications requiring high-precision temperature control.

- high stability: The physical and chemical properties of platinum are very stable, so platinum temperature sensors have good stability over long periods of time and are not susceptible to aging or drifting.

- Wide measuring range: Platinum temperature sensors operate over a wide temperature range from -200°C to +850°C and are adapted to many industrial and scientific applications.

- good linearity: Platinum temperature sensors have a good linear relationship between resistance and temperature, making them easy to calibrate and calculate.

- corrosion resistance: Platinum has excellent corrosion resistance and is suitable for use in harsh environments.

Preparation process

- Substrate preparation

- Photolithography

- Platinum film deposition

- reprocess

- heat up(annealing (metallurgy))deal with

One of the deposition processes preferred magnetron sputtering; magnetron sputtering preparation of thin film platinum temperature sensors have the advantages of good uniformity of the film layer, strong adhesion, high process controllability, low temperature deposition, suitable for complex shapes of the substrate, environmental protection and safety, as well as high cost-effectiveness. This makes magnetron sputtering a widely used technology in the manufacture of modern thin-film sensors, which can meet the needs of diverse applications and enhance the performance and reliability of sensors.

Effect of magnetron sputtering platinum plating on platinum temperature sensors

Optimizing Sensor Performance

Enhancement of film quality: The magnetron sputtering process produces high purity and homogeneous platinum films, which are essential for improving the performance of platinum temperature sensors. The homogeneous film ensures a linear and precise change in resistance, which improves the accuracy and stability of temperature measurements.

Control thickness: The magnetron sputtering process allows precise control of the thickness of the Pt film, which has a direct impact on the response time and sensitivity of the sensor. A thinner Pt film improves the response time of the sensor, while a thicker Pt film improves the durability and stability of the sensor.

surface quality: Magnetron sputtering produces a dense and smooth platinum film on the surface of the substrate, which contributes to the sensor's corrosion and wear resistance and extends its service life.

Improved production consistency

Highly repeatable: The magnetron sputtering process has good repeatability and ensures consistent quality and performance of Pt thin film sensors from batch to batch. This is critical for mass production and quality control.

automated production: Magnetron sputtering equipment can realize automated production, improve production efficiency and reduce costs, while reducing the impact of human factors on product quality.

Microstructure and adhesion

Improved microstructure: Magnetron sputtering is capable of generating Pt films at lower temperatures, avoiding thermal damage to the substrate from high temperature processes. This process produces thin films with good grain structure and low defect density, which enhances the performance of the sensor.

Enhanced adhesion: Magnetron sputtering produces a platinum film with good adhesion to the substrate, which prevents the film from peeling or coming off during use. This is particularly important for the stability and reliability of the sensor in harsh environments.

We offer Magnetron sputtering foundry customization services, Feel free to leave a message to inquire.

In-depth understanding: Introduction, types and applications of electron microscope carrier mesh (copper mesh)

In-depth science: introduction, types and applications of electron microscope carrier mesh (copper mesh) Electronic display

Difference between LPCVD and PECVD

Difference between LPCVD and PECVD By high in low voltage environment

.jpg)