Principles and Applications of Optical Coating Technology

The process principle of optical coating mainly involves the deposition of one or more thin films with specific optical properties on the surface of optical elements (e.g., lenses, mirrors, prisms, etc.) to control the reflection, transmission, absorption and scattering of light. These films alter optical properties through interference, absorption and scattering effects.

Principles of Optical Coating

interference effect

Optical coatings achieve the purpose of controlling reflection and transmission by depositing one or more layers of thin film material with specific thickness and refractive index on the surface of an optical element, utilizing the interference effect of light. When light passes through a medium with different refractive indices, partial reflection and partial transmission will occur at the interface of the medium. If the thickness and refractive index of the multi-layer film is properly designed, the light waves reflected from different layers can interfere with each other, thus changing the intensity of the reflected and transmitted light.

monolayer

Single-layer optical coatings are the simplest form, usually anti-reflective (AR) films. It works by selecting the appropriate film material and thickness so that the phase difference of the reflected light is 180 degrees, thus canceling each other out. This can dramatically reduce reflected light and increase transmitted light. For example, for a film with a refractive index of n and an optical thickness of a quarter wavelength (λ/4), this effect can be achieved.

multilayer membrane

Multilayer optical coatings consist of multiple thin film layers of different materials, each layer typically a quarter wavelength thick or a multiple thereof. By precisely controlling the thickness and refractive index of each layer, more complex optical properties such as broadband anti-reflection, high reflection, and filtering can be realized. Combinations of these film layers can be designed to be very complex to meet specific optical performance needs.

Material Selection

The selection of optical coating materials is critical. Commonly used materials include oxides (e.g., silica, alumina), fluorides (e.g., magnesium fluoride) and metals (e.g., aluminum, silver). These materials have different refractive indices and absorption properties, and choosing the right material and combination can achieve the desired optical performance.

Types of Optical Coatings

- Anti-Reflective Coatings (AR)

- High Reflective Coatings (HR)

- Beamsplitter Coatings

- Filter Coatings

- Polarizing Coatings

- Enhancement Coatings

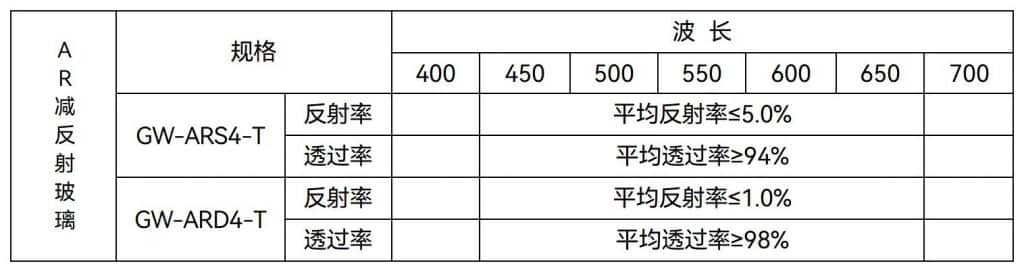

Product Specification

Angle of incidence: 45° polarization: (P+S)/2

Angle of incidence: 5°

For special material customization needs, please contact us!

We offer Magnetron sputtering foundry customization services, Feel free to leave a message to inquire.

Atomic Layer Deposition (ALD) Principles, Benefits, and Applications

Atomic Layer Deposition (ALD) Principles, Benefits and Applications Atomic Layer Deposition

Difference between ICPCVD and PECVD preparation of silicon nitride films

Difference between ICPCVD and PECVD preparation of silicon nitride films IC

Silicon nitride thin film window applications Materials Science丨Semiconductor丨Bioscience

Silicon nitride thin film window products are used in a wide range of applications in materials science, semiconductor production and analysis, and bioscience. Our high quality products provide high resolution imaging capabilities for a wide range of sample types and sizes.

.jpg)