Properties and applications of titanium nitride

Titanium nitride film (TiN) is an important hard film coating materials, is also the first industrialization and widely used film coating materials. TiN film has a high melting point, high hardness, high temperature chemical stability and excellent thermal conductivity, electrical conductivity, optical properties, biocompatibility, etc., applicable to high temperature, wear resistance, low radiation glass coating and medical and other fields. Due to its unique color and luster, it is often used as a gold coating in the jewelry industry.The wide application of TiN film puts forward higher requirements on the film quality, and the preparation of TiN film with higher hardness, higher wear resistance and better bonding strength has become a hotspot in the research of domestic and foreign hard coatings.

Properties of titanium nitride

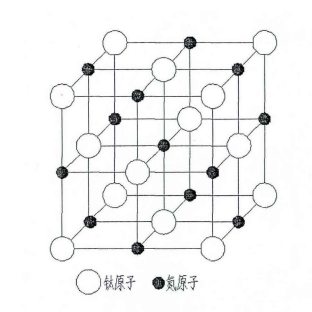

Ti and N can form a variety of solid solutions and compounds, common Ti-N compounds have Ti2N and TiN two, the metal titanium (Ti) in the interstitial phase is a dense row of hexagonal dot matrix or face-centered cubic dot matrix arrangement, non-metallic nitrogen (N) atoms fill the interstitial position in the Ti crystals. Ti2N structure, the metal Ti atoms are arranged in dense rows of hexagonal dotted line, and the N atoms in the gap position; TiN structure, the metal Ti atoms are arranged in face-centered cubic dots, N atoms in the octahedral gap position, forming a typical B1-NaCl structure, as shown in the B1-NaCl structure. In the Ti2N structure, the metal Ti atoms are arranged in a dense row of hexagonal dots, and the N atoms are in its interstitial positions; in the TiN structure, the metal Ti atoms are arranged in a face-centered cubic dot matrix, and the N atoms are in the interstitial positions of its octahedra, which forms the typical B1-NaCl structure as shown in the figure.

Physical Properties:

- Color: Titanium nitride has a golden yellow appearance and is often used for decorative coatings because of its color.

- Hardness: TiN has high hardness, Vickers hardness can reach 2000-2500 HV, microhardness is about 21GPa, with excellent wear resistance.

- Melting point: The melting point of titanium nitride is up to 2930℃, which is suitable for high temperature environment.

- Density: The density of TiN is 5.22 g/cm³.

- Thermal conductivity: The thermal conductivity of TiN is about 30 W/m-K, which has good thermal conductivity properties.

- Elasticity: Modulus of elasticity up to 590 GPa.

- Thermal Expansion: The coefficient of linear expansion is 9.35×10-6°C (20°C-1000°C).

Chemical Properties:

- Chemical stability: TiN has good chemical stability in air and oxidizing environment, not easy to oxidize and corrode.

- Corrosion resistance: Titanium nitride has good corrosion resistance to many chemicals (e.g. acids and alkalis).

Electrical properties:

- Conductivity: TiN has metallic conductivity with a resistivity of about 20 µΩ-cm.

- Electronic structure: TiN has a mixture of metallic and covalent bonding properties. The electronic structure gives it excellent electrical and thermal conductivity.

Applications of Titanium Nitride

Coating field

TiN coating is one of the earliest researched and largest market share of nitride coatings. It is widely used as coating layer for various cutting tools, bearings and molds to enhance their service life and reduce economic loss. Compared with ordinary uncoated tools, the coating tool cutting speed increased 25%~70%, machining accuracy increased 0.5~1 level, tool consumption costs reduced 20%~50%, wear resistance increased 2~10 times, service life extended exponentially. It can be seen that TiN coating has a great role in promoting industrial production.

Microelectronics

The excellent conductivity of TiN in the field of microelectronics can be used as semiconductor device electrodes, buffer layers and barrier layers, etc.. In integrated circuits based on Si materials, Cu has become the most advantageous wiring material for preparing ultra-large integrated circuits due to its low resistivity and excellent resistance to electromigration. However, Cu tends to diffuse in Si and its chemical substrates, which seriously affects the performance of semiconductor devices. In order to solve these problems, a thin layer of TiN with low resistivity and good thermal stability is added between the Cu film and the substrate, i.e. TiN barrier layer, which can effectively improve the adhesion strength of the Cu film while hindering the diffusion of Cu. TiN barrier layers have been widely used in integrated circuits. The Cw/TiN/Si multilayers deposited with TN of 40 nm thickness were heat-treated at 575° C for two hours, and the TiN films still had a high blocking effect.

Coating field

With the improvement of modern living standards, simple and practical decorative materials can no longer meet people's higher level of spiritual needs. The color similar to gold has a special attraction to people, which makes people invest a lot of money and time in the field of gold imitation. In the past, Cu-based gold-imitating alloy or chemical gold-plating method has high cost and high environmental pollution, which is difficult to be developed sustainably.TiN thin film has similar optical properties with gold, silver and other precious metals, and TiN thin film is non-toxic and inexpensive, which is ideal for modern gold-imitating materials. TiN thin films were prepared by magnetron sputtering method to investigate the effect of nitrogen content on the color of the films, and the results show that the color of TiN thin films changed in various ways with the increase of N/T ratio. The variable and controllable color makes TiN films have a broad application prospect in the field of decoration and jewelry.

Medical field

TiN is highly biocompatible and can be used in clinical medicine and bionics. The internal environment of living organisms is very complex, the traditional medical metal materials are easily affected by the internal environment of living organisms, resulting in the degradation of the metal materials themselves, and more seriously, the deterioration of the material will be harmful to the organisms, and the deposition of TN ceramic coatings on the surface of the medical metal materials can effectively improve the corrosion resistance and biocompatibility of the metal materials. TiN/Ti composites were prepared by ion plating technology and tested in animal body, and the results showed that TiN/Ti composites possess stronger adaptability and biocompatibility than pure Ti and medical stainless steel. In dentistry, TiN materials are mainly used in the surface coating of cutting tools, implants and dentures to slow down the corrosion of implants in the oral electrolyte environment and enhance the service life of medical devices.

Other areas

TiN films are semi-transparent in the visible region and highly reflective in the infrared region, and have a promising application in the field of smart glass.TiN's melting point is higher than that of most of the over-metal nitrides, while its density is just the opposite, and this special property makes it possible for TiN to be used in the direction of refractory materials. Advances in modern material preparation techniques have given TiN more scope for applications in directions such as energy storage, batteries and detectors. Titanium nitride is one of the most important and indispensable materials for modern industrial production due to its simple preparation and excellent performance.

We offer Coating (micro- and nanofabrication) process customization services, Feel free to leave a message to inquire.

Magnetron sputtering丨influence on the quality of thin films

Magnetron sputtering 丨the reasons affecting the quality of thin films Magnetron sputtering has a high speed, low

Atomic Layer Deposition (ALD) Principles, Benefits, and Applications

Atomic Layer Deposition (ALD) Principles, Benefits and Applications Atomic Layer Deposition

Physical Vapor Deposition (PVD) Classification, Characteristics, and Applications

Classification, Characteristics, and Applications of Physical Vapor Deposition (PVD) Physical Vapor

.jpg)