Difference between LPCVD and PECVD

Difference between LPCVD and PECVD By operating at high temperatures in a low-pressure environment, L

Home " Product " Electron microscope consumables " Perforated Silicon Nitride TEM Window Grids

Advantages of silicon nitride films.

Our product advantages.

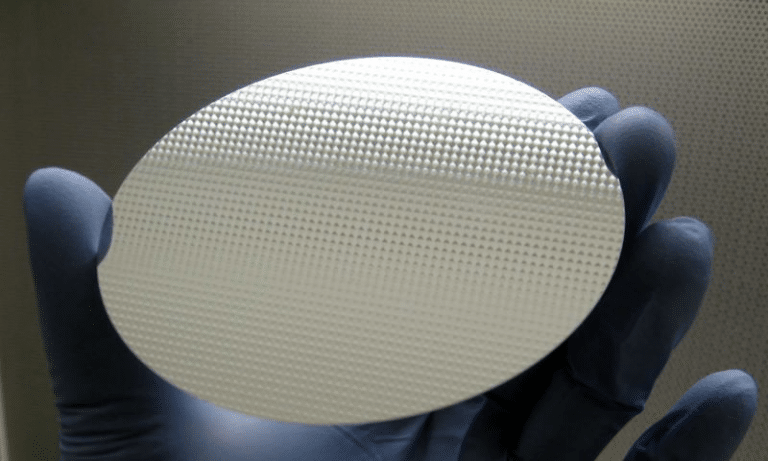

Perforated silicon nitride film windows have the following advantages over ordinary silicon nitride film windows without perforations:

Improved material transmittance: Perforated silicon nitride film windows have higher transmittance because the holes reduce the chance of light being absorbed by the film, thus increasing transmittance, which makes it more suitable for applications requiring high transmittance, such as optical analysis.

Improved sampling speed: The openings in the perforated silicon nitride film window promote sample aeration, reducing isolation between the sample and the environment, thereby reducing the time to acquire data. This gives it an advantage in applications where high aeration and acquisition speed are required.

Improving material stability: Perforated silicon nitride thin film windows can reduce the internal stress and thermal expansion coefficient of the material during the preparation process due to its reasonable structural design, thus improving the stability and reliability of the material.

Improved durability: The perforated silicon nitride film window is structurally designed to improve its resistance to corrosion and wear. This gives it an advantage in applications that require prolonged use.

Improved flux: The large open area of the perforated silicon nitride film window allows for improved flux. This gives it an advantage in applications where high flux is required.

In summary, silicon nitride thin film windows with holes perform better in terms of optical properties compared to ordinary silicon nitride thin film windows without holes. Therefore, in material characterization applications, silicon nitride thin film windows with holes are usually a better choice.

Difference between LPCVD and PECVD By operating at high temperatures in a low-pressure environment, L

Principles and Applications of Optical Coating Technology The process principles of optical coating are mainly involved in the optical element

Influence of the annealing process on platinum resistors In the field of high-precision temperature measurement, thin-film-type platinum resistors are used because of

Magnetron sputtering丨the process of making platinum temperature sensors In modern technology, temperature sensors

.jpg)